Barrels Green Mountain Rifle Barrel Co. Parts & Upgrades December 15, 2015

If you want to improve your AR’s performance and stand out from the crowd, you have to check this out…

Arguably, nowhere in the shooting industry are there as many variations on a theme as what you find in the AR world. With hundreds of manufacturers producing their individual spins on the same products (just think handguards and grips, for example), the possible iterations of the AR-15 seem endless.

Unfortunately, such diversity can also breed familiarity. Aside from the KeyMod interface system, when was the last time a new AR platform innovation made you stop and go, “Coooool…?”

For us, that happened a few months ago when we learned that Green Mountain Rifle Barrel Company had just introduced an all-new barrel for the AR platform.

The Green Mountain Difference

If you are a veteran shooter, you already know that Green Mountain Rifle Barrel products sit at the top of the list when it comes to high-quality rifle barrels. Their barrels have delivered championship wins across the competitive shooting landscape, and the precise engineering and sub-MOA accuracy of their AR barrels are well-documented. By themselves, these are the go-to barrels for anyone looking to enhance the quality and performance of their rifle.

Then along comes something completely different—something that combines a precision barrel with a look that is totally fresh for the AR marketplace. Oh, and you can factor in a subtle, albeit desirable performance enhancement while you’re at it.

Finned Is In (or it soon will be!)

We are talking about the GM-M11 Finned Barrel in 5.56 NATO. That is “finned,” as in similar in style to the barrel profiles found on the Thompson submachine gun or a Soviet-era DShK, for example. When we saw the GM-M11, we knew we had to have one. What better way to jazz up one of our plebian ARs than with a high-performance and highly unconventional barrel like this?

The Green Mountain GM-M11 Ribbed Barrel for 5.56mm NATO comes ready to install. The durable Black Nitride finish is the perfect visual and performance compliment to the ribbed profile. This is a 16-inch barrel with a 1:7 twist and M4 feed ramp extension.

Now before you take us for being members of the googly eyed tacticool fan club, understand that we were under no illusions that having ribs on our AR barrel would turn our 5.56 into a 200-meter bullet cutter. Sure, any Green Mountain barrel would certainly provide tighter groups and enhanced durability over our run-of-the-mill stock barrel, but we reached for the GM-M11 for one reason in particular…it’s sexy.

The Nitty Gritty

The GM-M11 is a 16-inch barrel drilled for a carbine-length gas system. It is made of 4150 steel with a finned profile (of course) and comes treated with a Black Nitride finish. The barrel is not pinned for MILSPEC front sight gas blocks, but it is ready to accept standard .750-inch low-profile gas blocks. Rifling twist is 1:7, and the barrel includes the M4 feed ramp extension. Total weight is 1.7 pounds, which is about the same or a shade lighter than most conventional M4 profile barrels.

The 11.5-inch GM-M11S barrel (left) is perfect for making an SBR or, as we did, an AR pistol. Both the ribbed 11.5- and 16-inch barrels include the M4 extension with feed ramps (right).

In addition to the GM-M11, Green Mountain also makes an 11.5-inch SBR/pistol-length version of the ribbed barrel, PN GM-M11S. It is identical to the GM-M11 except for the length.

Making the Swap

We spent around a half-hour swapping our standard M4 barrel with the Green Mountain GM-M11, utilizing the original gas block, gas tube, flash hider, and barrel nut. The total cost we had in the conversion was the price of the barrel. The installation was straightforward, and the only specialty items required to make the swap was a ft/lb torque wrench, barrel nut wrench, and an upper receiver vice block. To make sure we performed the conversion correctly and that the barrel and bolt carrier group combo would work together, we used go/no-go gauges to check for proper headspacing. Finally, we performed a complete safety/function check to be sure the rifle would work properly and safely on the range.

(NOTE: THE FOLLOWING IS AN OVERVIEW OF THE BARREL SWAP PROCESS. IT DOES NOT PROVIDE THE NECESSARY DETAILS TO FOLLOW AND CORRECTLY PERFORM THIS WORK. THIS SEQUENCE IS INTENDED ONLY TO ILLUSTRATE THE GENERAL PROCESS OF REMOVING AND INSTALLING A BARREL. FOR SAFETY REASONS, THIS PROCESS SHOULD ONLY BE PERFORMED BY A QUALIFIED GUNSMITH.)

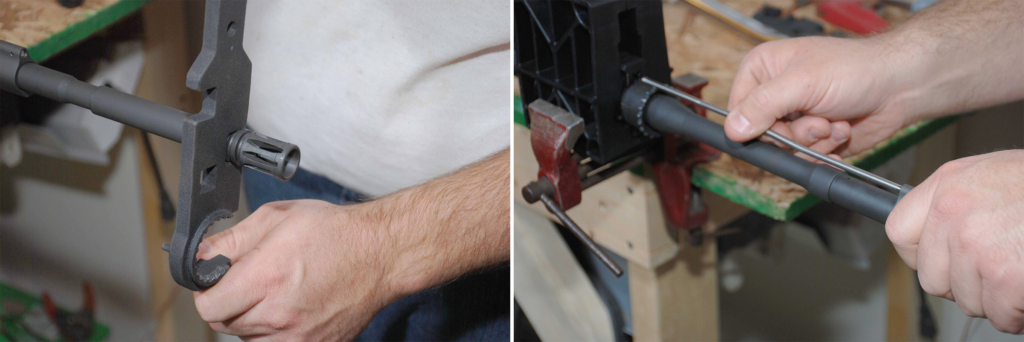

After rendering our rifle safe, we separated the upper and lower receiver assemblies, removed the bolt carrier group, and secured the upper receiver assembly in an upper receiver vice block. Next, we removed the flash hider and the gas block/gas tube assembly from the barrel.

Using a proper barrel nut wrench, we removed the barrel nut.

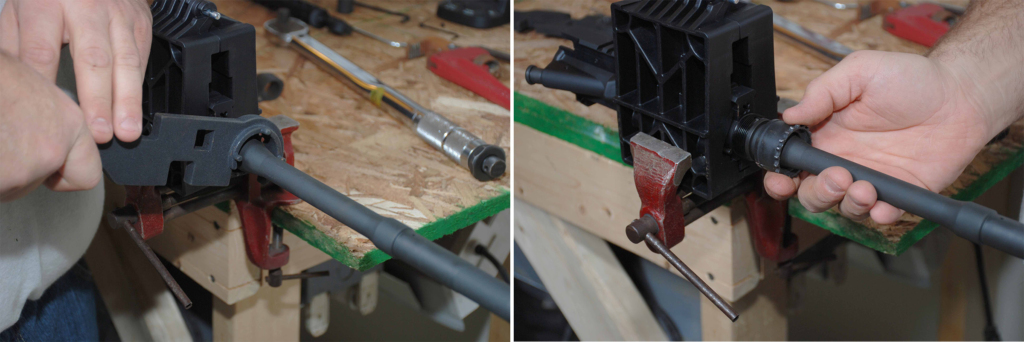

With the barrel nut removed, we pulled out the old barrel and inserted the new Green Mountain GM-M11.

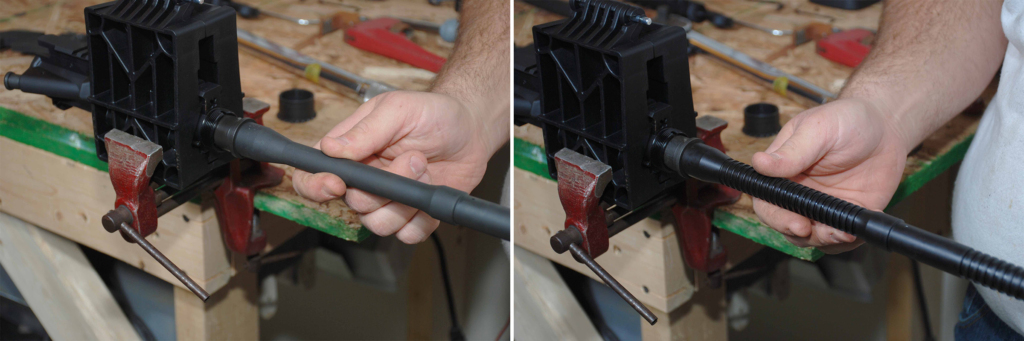

A torque wrench is required to tighten the barrel nut to the proper specification, and to line up the next barrel nut groove with the gas tube channel. Once aligned, the gas tube/gas block assembly is installed on the barrel.

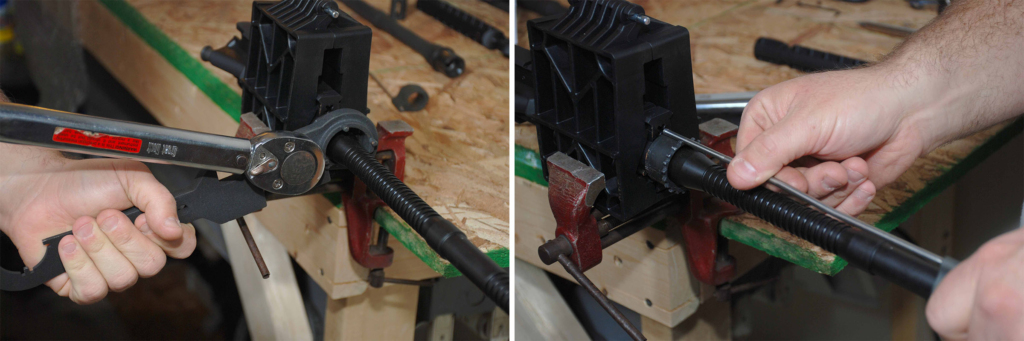

We also used the torque wrench/barrel nut wrench combo to tighten the flash hider to the proper specification. With the barrel correctly installed, we reinstalled our original hand guard.

IMPORTANT SAFETY NOTE: Although AR building and modifying are common practices for veteran firearms owners, any work that involves the disassembly, assembly, or swapping of the critical AR rifle systems, such as the barrel, bolt carrier group, gas system, trigger, safety selector, and other components/systems should be performed by a trained and qualified gunsmith or experienced firearm technician. Furthermore, before firing a modified or reassembled firearm, you should use go/no-go gauges to ensure the headspace is within specifications, and that the firearm passes a thorough safety/function check.

Final Assessment

Once completed, our rifle looked as wicked as we thought it would. The barrel’s Black Nitride finish was a welcome upgrade—both visually and functionally—to our dull manganese phosphate barrel, and, of course, the finned barrel profile is going to make all of our range mates jealous.

One additional benefit that we somewhat anticipated but weren’t sure we would achieve was a drop in barrel operating temperatures. The GM-M11’s fins obviously offer more surface area for cooling than that of a standard M4-style barrel. One-hundred round comparisons between another M4 barrel and the GM-M11 revealed a 4-7 degree F reduction in barrel temperature with the Green Mountain model. That’s not a huge difference, but we’ll take any advantage we can get.

After building our rifle, we couldn’t help but take the next step and build an AR pistol with the Green Mountain 11.5-inch GM-M11S ribbed barrel. The upper receiver build for the pistol was no different than that of the rifle. For the lower receiver assembly, however, we replaced the rifle buffer tube assembly with a pistol buffer tube assembly and installed the Sig Sauer SBX Pistol Stabilizing Brace. And before you say, “Hey…that’s an SBR!” know that the SBX brace is AFT-compliant and does not alter the pistol’s NFA classification.

So, if you’ve grown weary from swapping out hand guards and buttstocks just to keep your AR fresh and exciting, you might want to get some ribs. You’ll also find that the GM-M11 is “cool” in more than just looks!

SOURCE – Green Mountain Rifle Barrel Company

Article Copyright 2015 by ArmedDaily.com; promoted by Green Mountain Rifle Barrel Company